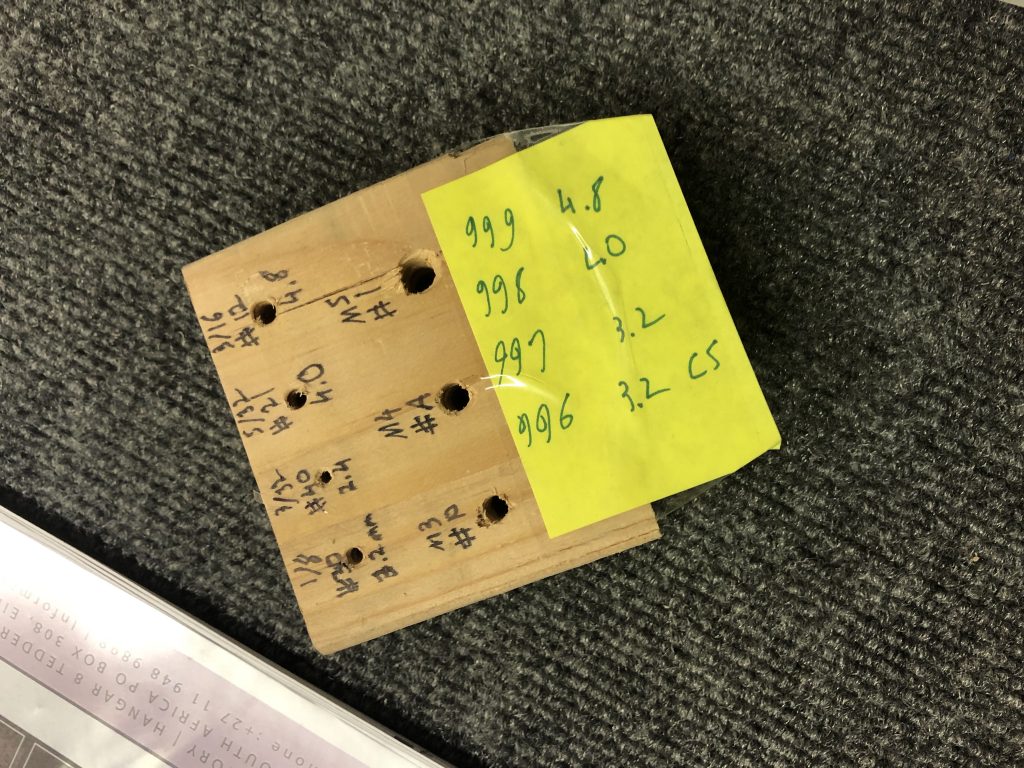

The kit has a lot of different measurements, so I’ve compiled some information for drilling, countersinking and rivet sizing. I’ve also made myself a handy little reference block out of wood so I can quickly check sizing while I’m in the garage.

Hole alignment

The factory has already drilled most of the holes, except for a few that need match drilling like the fiberglass tips.

For some minor alignment issues, I’m using some chucking reamer bits to correct the hole.

Countersinking & Dimpling for flush riveting

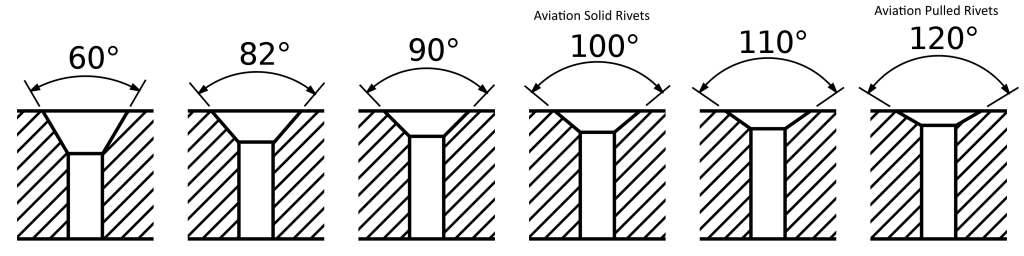

Since the project is using Pulled Rivets, the angle of the countersunk pulled rivets is 120 degrees, as opposed to solid aviation rivets, which use 100 degrees.

For that purpose, the factory has specific dimple dies for the thinner parts that are dimpled for flush riveting.

Some of the parts, such as the fiberglass tips or thicker metal pieces (from the EAA Sheet metal course I took, I learned the rule of thumb is metal ticker than 0.04 inches) need to be countersunk. To be consistent when countersinking, I use a Microstop Countersink drill guide and a 120 degree countersink pilot cutter.

I did a write-up as part of this post of why it’s so important to use the correct size countersinking pilot.

Rivet sizing

| Rivet Size Metric | Rivet Size Fractional Inches | Drill size |

|---|---|---|

| 2.4 mm | 3/32 | #40 |

| 3.2 mm | 1/8 | #30 |

| 4.0 mm | 5/32 | #21 |

| 4.8 mm | 3/16 | #12 |

Rivnut sizing

| Rivnut Size Metric | Rivnut outside diameter | Drill size | Closest Numbered Drill size |

|---|---|---|---|

| M3 | 4.9 mm | 5 mm (13/64) | #10 |

| M4 | 5.9 mm | 6 mm (7/32) | #A |

| M5 | 6.87 mm | 7 mm (9/32) | #I |

Hi Philip, thank you for taking the time to document & then share your build log;

Having watched the development of the Sling2 then the Sling4, and now the TSI I was wondering if you could tell me please what type of counterunk rivets are used on the forward part of the fuselage & leading 1/3 edge of the wings, ie; Aluminium Stainless or Monel, & 120° fully countersunk or perhaps just a lower profile head? I am aware Cherrymax do make stainless & Aluminium pulled countersunk rivets however I seem to recall reading or perhaps listening to an interview with Mike Blythe early in the TSI development stage saying TAF was looking at countersunk rivets that were from ? I think Germany?

Thank you again for a very detailed build log.

Cheers Glenn – Down Under

Hi, They are fully countersunk pulled (120deg) Aluminum/Stainless rivets from a German company called Gesipa.

Most builders have filled in the rivets with a filler prior to painting, so you end up with a flush finish.

Thanks Phillip I will look these up and study the specs

Cheers, Glenn

Just Started my Sling TSI Build and doing the Horizontal Stabilizer. The two dimple dies provided in the kit seem pretty cheap, and the o ring is so big on the shaft the die doesnt really go into my DRT2 Dimple machine. That being said, do the holes need to be drilled out to a #30 before you dimple. I am coming from a Vans RV14 build, and the dimple die would always go into the hole. The dimple die provided will not go into these holes unless they are drilled. The information manual says the parts that require a 3.2mm rivet have a hole at 2.8mm punched, but does not say to enlarge it. Any information you have is great. Thanks, Tim.