Now that the Rudder is almost complete, I needed to make the wiring for the Anti-collision light permanent. The existing wire of the Aveo Posistrobe Minimax I’m using has 4 wires (ground, power, strobe, sync), so I needed to splice those onto the wire so I could run it through the structure.

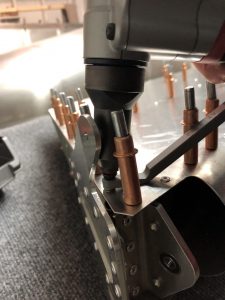

Since this is a permanent connection, I’m using Heat Shrink Solder Sleeves, which have solder in the center and when you heat it up, the solder melts and the sleeve shrinks down to create a good seal.

After that was done, I added some expandable braided Sleeving over the wire for extra protection.

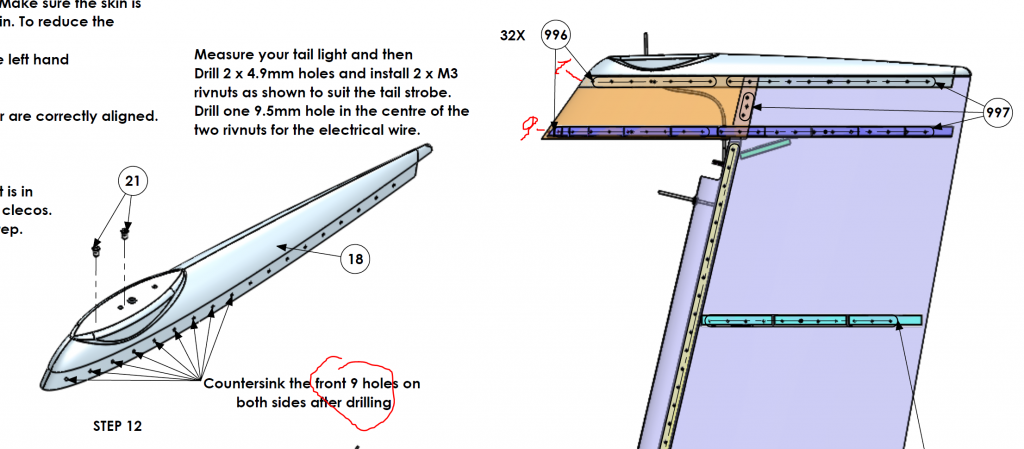

I up sized the hole for the wire to pass through the fiberglass tip using my step drill bits and then ran the wires through the structure and out the front hole, which I also had to drill up as per the instructions. After some more research, I replaced the rubber grommets with snap bushings. They last longer and for the front hole in particular, they hold on better since they snap in place.

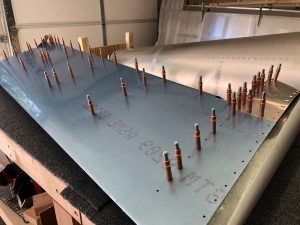

Here’s the light mounted and completed wiring done.

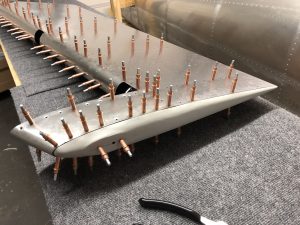

Now the last thing to do is close up the top. Inspired by a discussion from a while ago on the Sling Builders group, I was contemplating the idea of making the fiberglass tip removable using nut plates and screws, but I think I’ll end up just riveting it closed.