While the wait for the arrival of my Sling TSi kit continues, I got to do some sheet metal practice attending the EAA Sportair Sheet Metal workshop recently.

It was a two day weekend workshop that was held at the Seattle Museum of Flight Restoration Center, teaching the basics of sheet metal work with all sorts of various techniques used when building a sheet metal airplane.

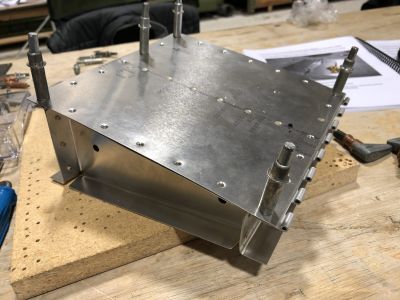

Over the course of the two days each participant made two practice pieces. The first one was to get a feel for the different techniques, from drilling, to deburring, to dimpling and countersinking. Here’s the first piece:

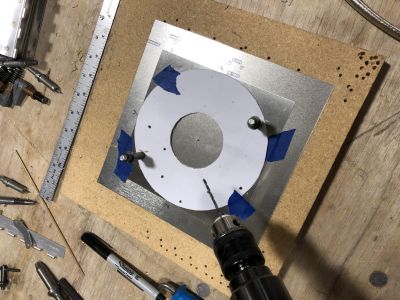

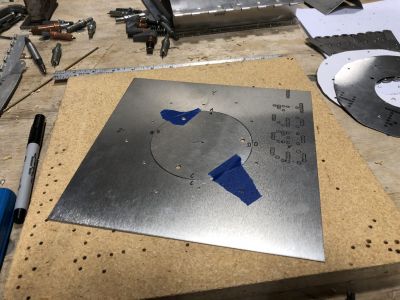

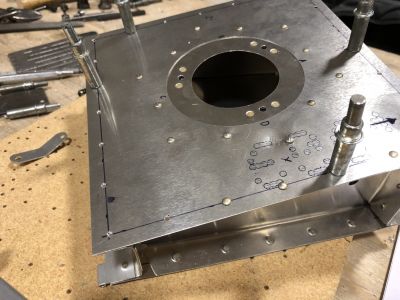

The second practice piece was a cross section of an elevator, where we had to bend rib pieces, practice more match drilling and dimpling and then fabricate a flush inspection plate held in place using nut plates. Here’s some images I took during the process:

All in all, it was a great workshop, a lot of learning and building confidence in the skills required to build your own airplane. So if you’re toying with the idea of building your own airplane from sheet metal, but are unsure about the work involved, this workshop is a great entry point.

While I likely won’t need to use some of the riveting techniques I learnt in the workshop, since the Sling assembly mainly uses pop rivets, it was still great to get a good understanding of the different techniques.

Here’s a final picture of all the practice of the workshop put together (with an airplane drawn as a bonus).