With one front seat assembled, time to complete the other one.

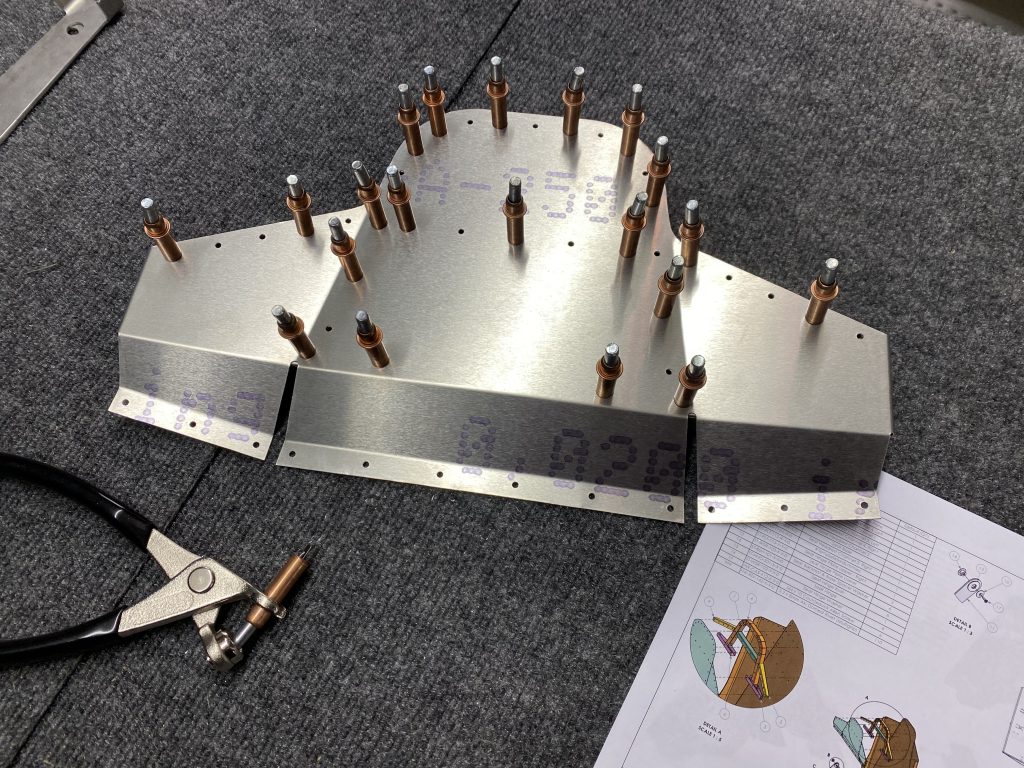

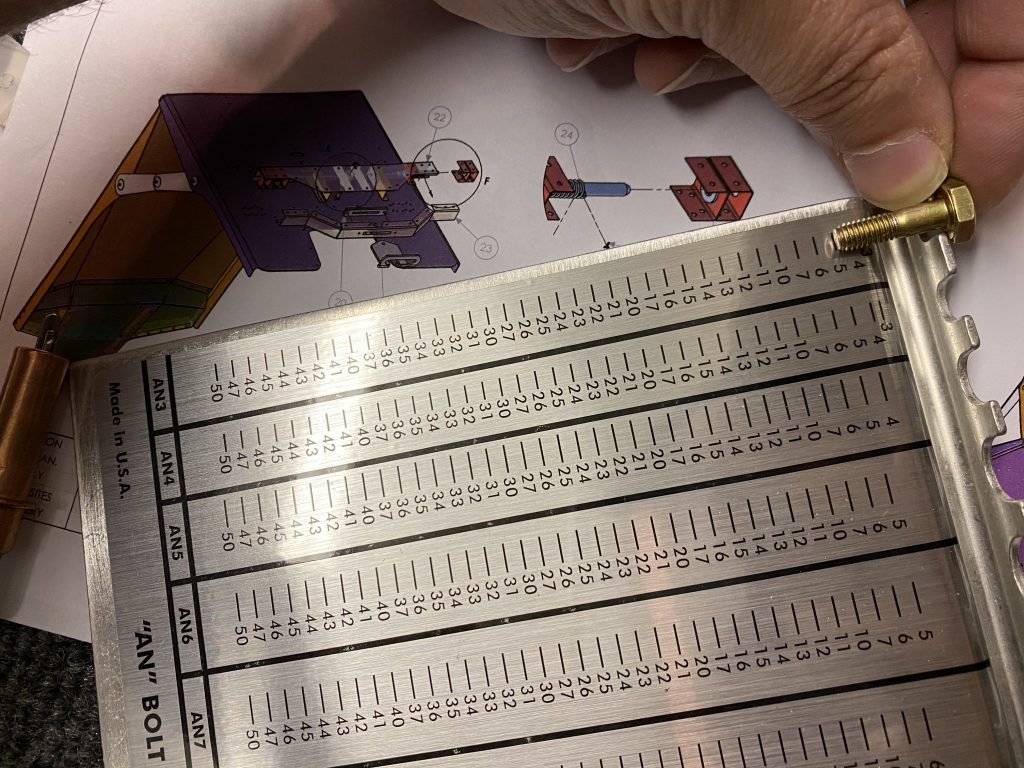

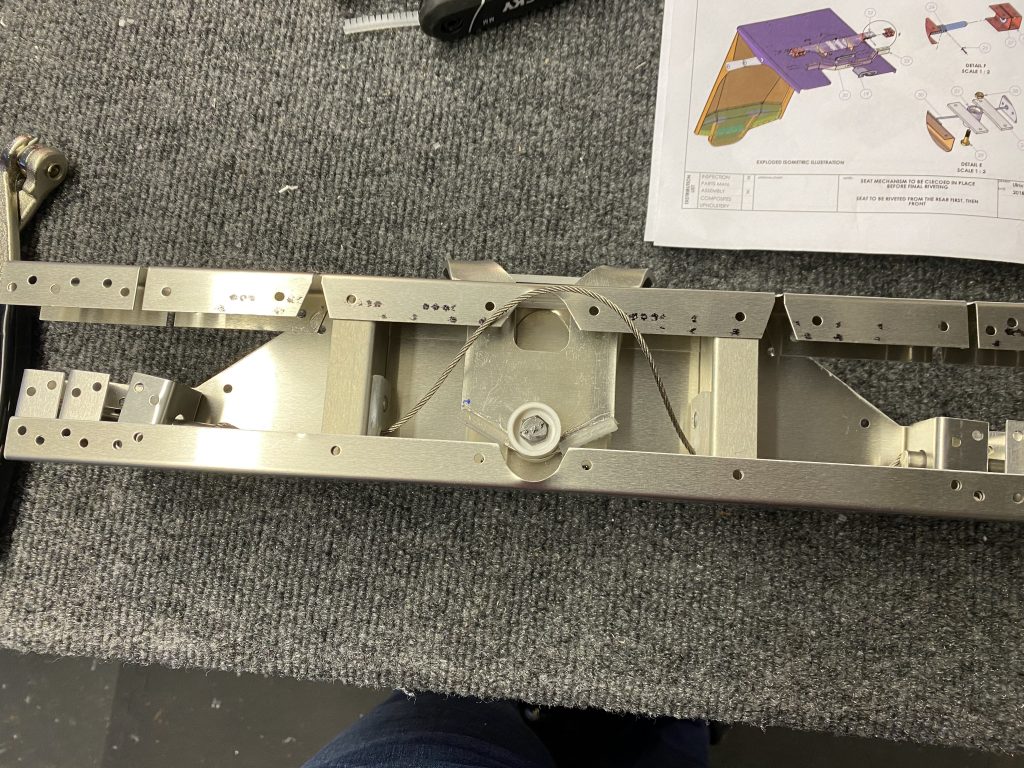

I got an AN3-6A bolt from a friend while waiting to get a replacement from TAF, so I was able to put together the seat locking mechanism for the seat.

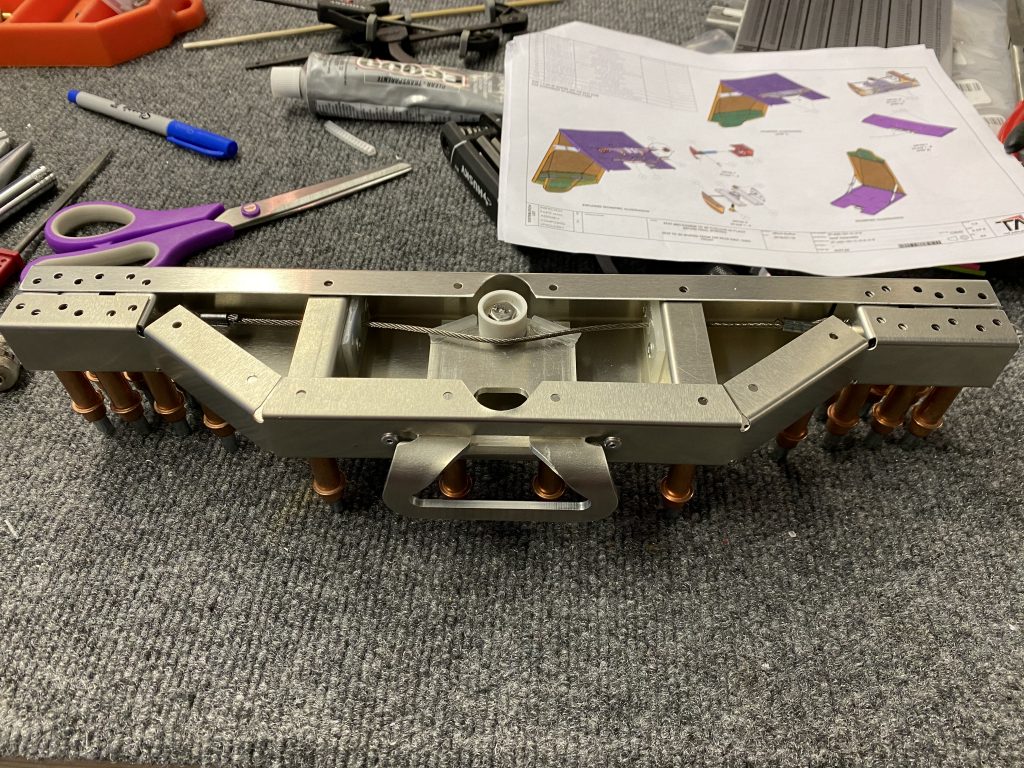

EDIT: after reading the Sling 4 instruction manual, I now believe the cable goes on the other side, so I’ll move it down before I close it up and rivet it in.

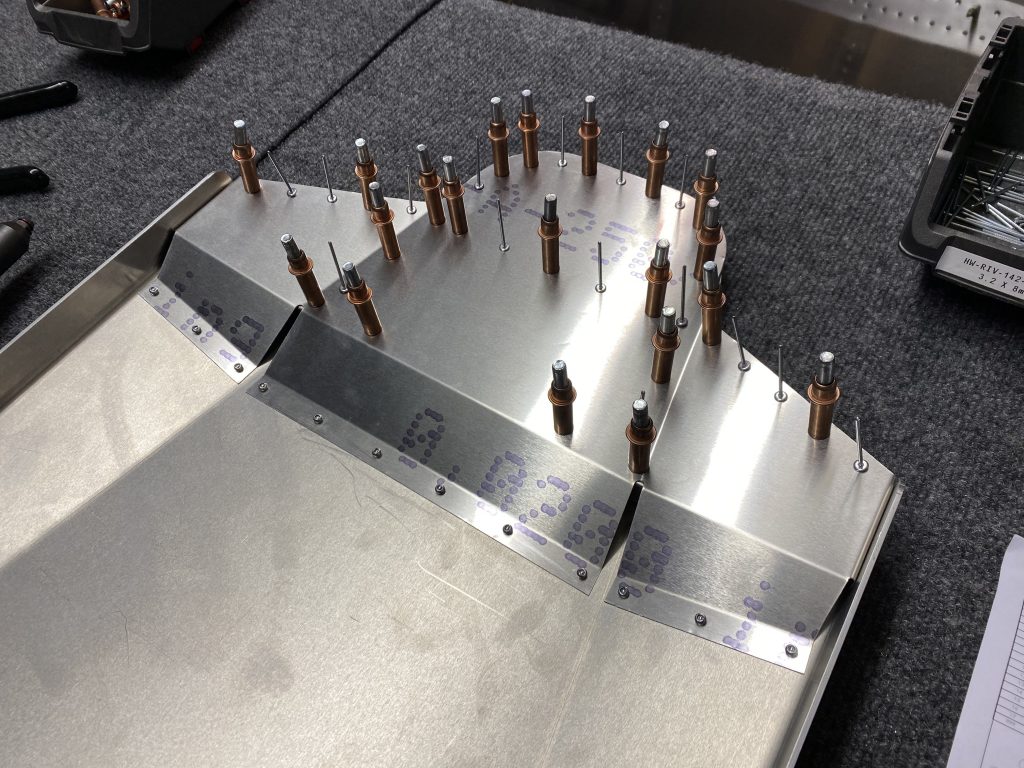

Now having figured out the complete assembly, I also assembled the mechanism for the second seat, but unfortunately, the steel cable assembly for the second seat is too long, so I put in an order for a replacement.

So one mechanism assembly completed, the other on hold.

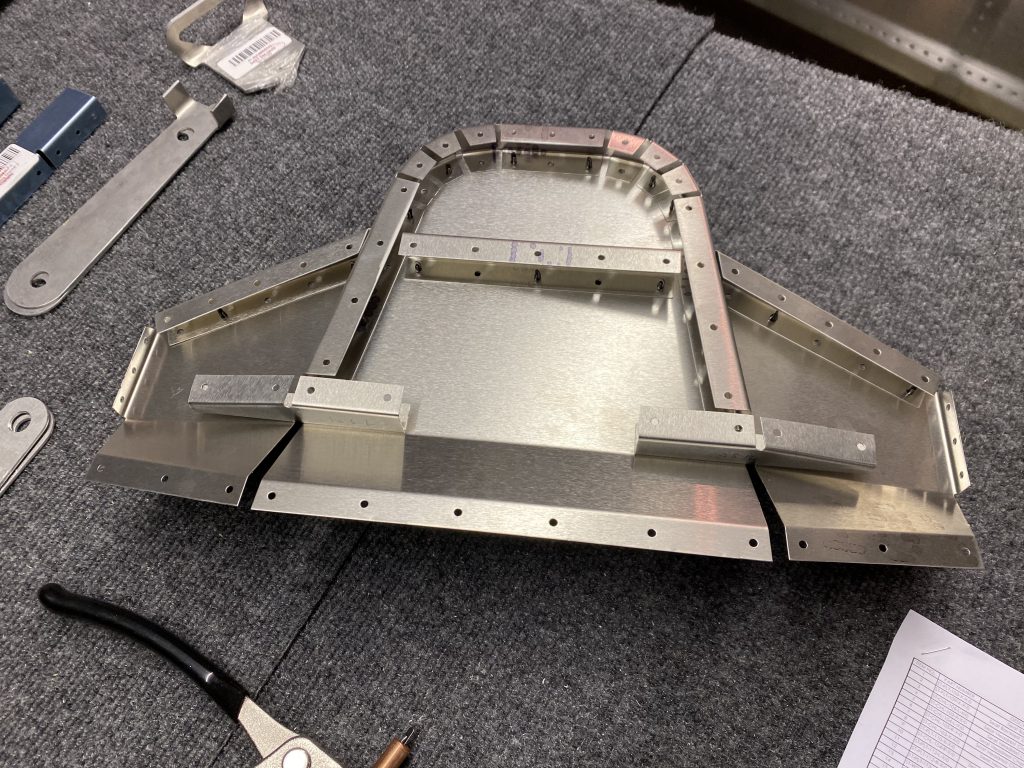

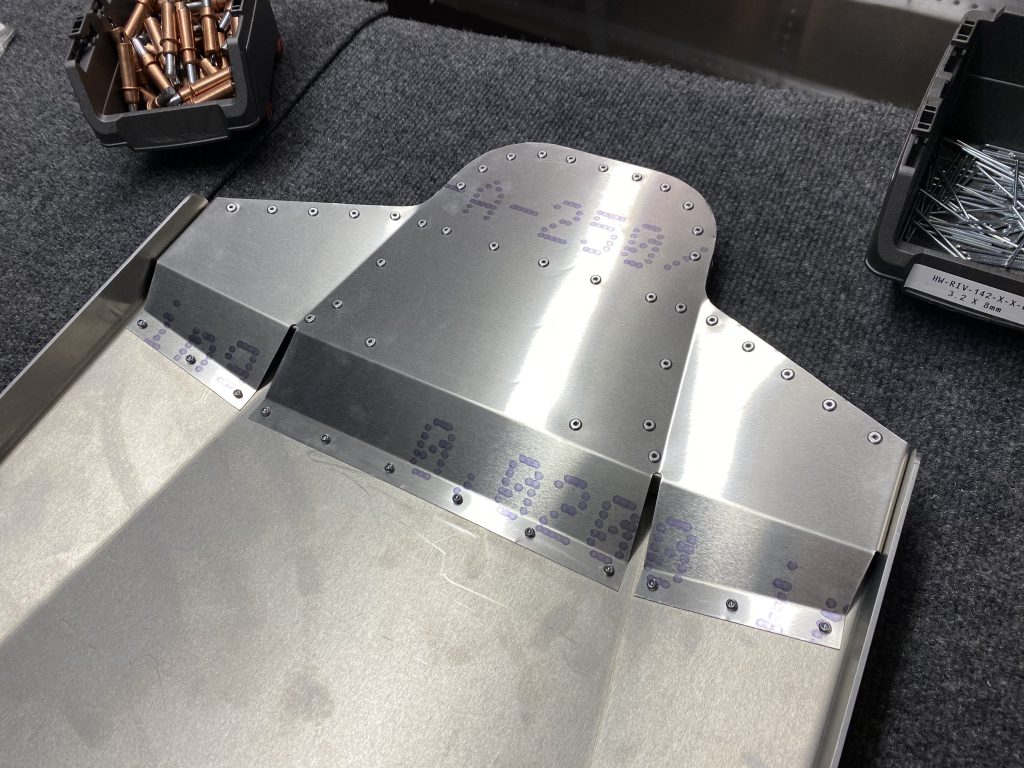

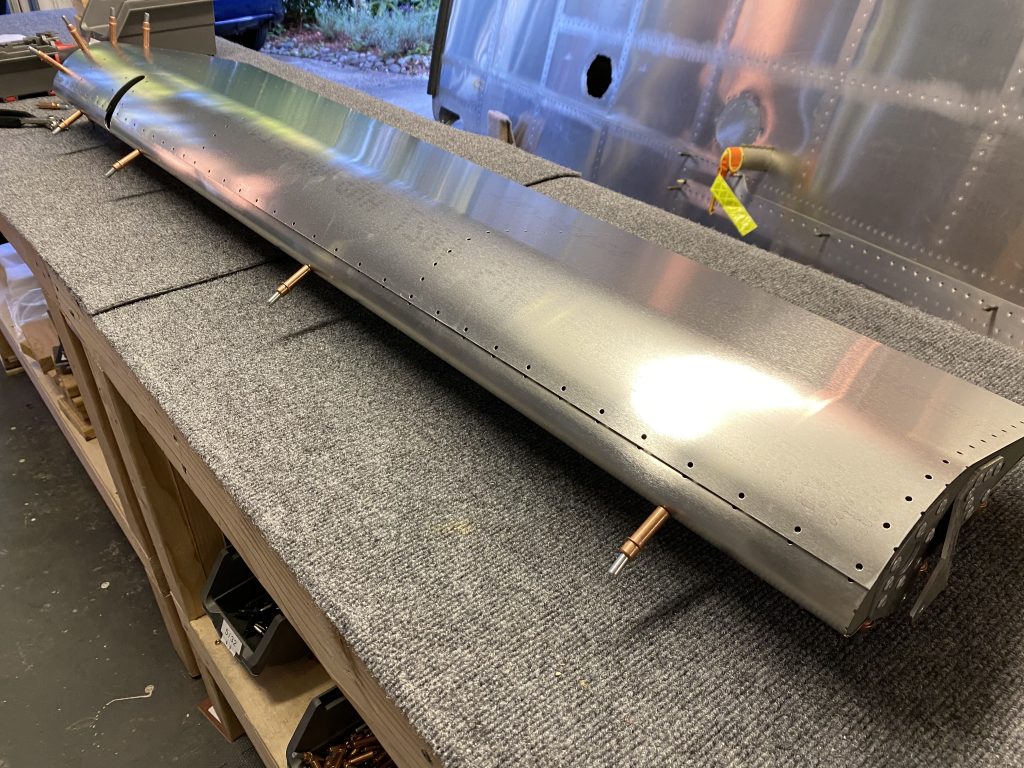

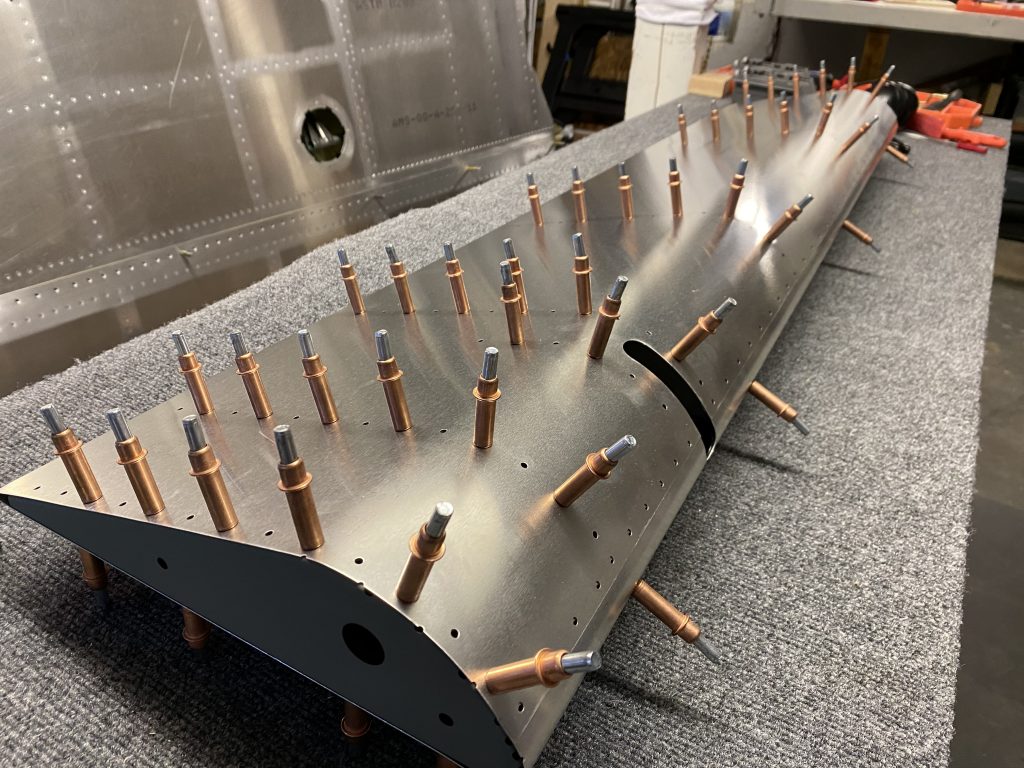

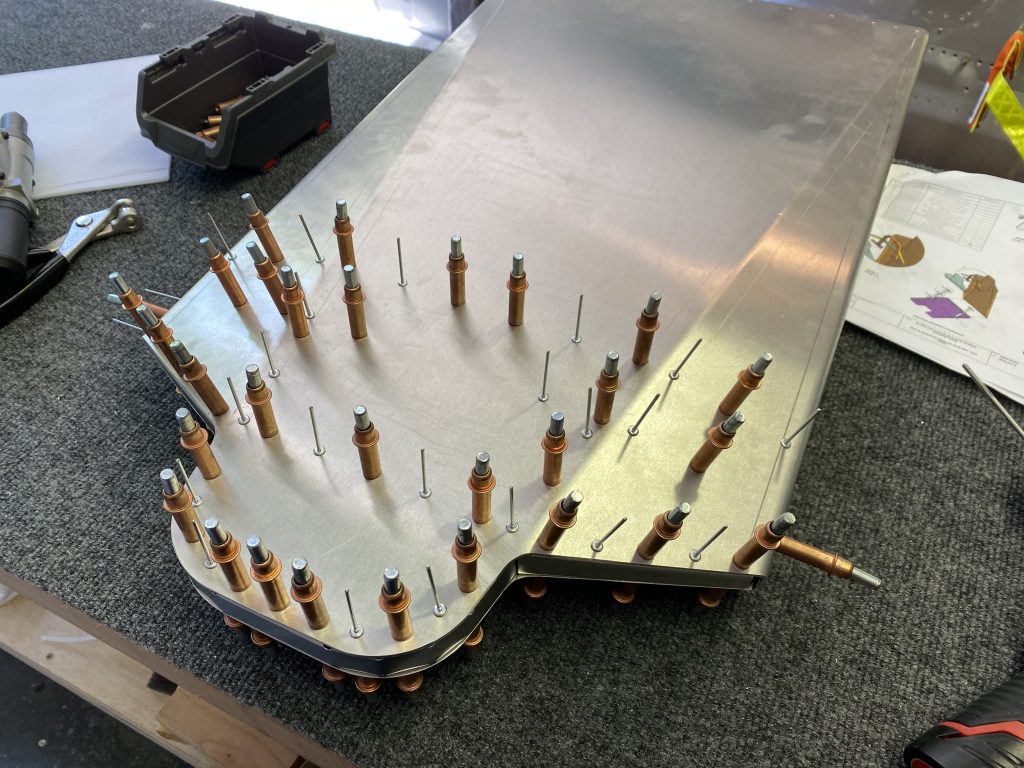

Then I completed assembling the second seat itself. When I built the other seat I noticed that I was missing some screws for the hinges and put in an order to get the missing screws, but I also remembered that I got some various metric screws from boltdepot a while back and luckily I had some countersunk M4x12 screws . Ialso found that there’s a typo in the instruction manual, which says they are M4x10, but the part number is HW-CAS-412-X-X-0 and they are actually M4x12. So I was able to put together the side hinges with those.

Now I just need some upholstery to make them a bit more comfortable to sit on. I ordered the upholstery a few weeks ago, so they should arrive in a few weeks hopefully.